If I see a leakage, I instinctively grab a screwdriver and start tightening all the hose clamps nearby. I have killed a few hose clamps as a result. This was also going on with the seawater pump for a while, until I realized that the pump axes is ‘open’ so seawater or oil will leak if one of the sealing rings are worn, makes sense I guess.

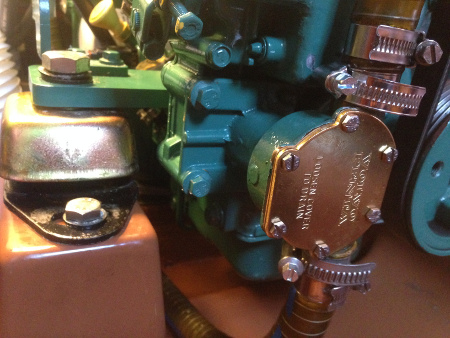

After browsing forums, getting a Volvo Penta wear kit and impeller kit and picking up a snap ring plier, I went to work on it, one afternoon. The pump is held in place by 4 bolts, where the 2 most accessible bolts have nuts. The 2 least accessible bolts are screwed into threads in the pump house itself. This 2 bolts require that, among other, one engine pad is removed for a minimum of access. At this point I realize that the 10 mm wrench key was missing from my toolkit, probably offered to Neptune at some point in the past. Just as well, because the afternoon had turned into evening.

Day 2 I got the pump removed. It took longer than you would think. After removing the gear, it became clear that the bent snap ring plier I brought was no good, I needed a straight on.

I took the pump to my tools (larger collection of tool at home, than in the boat), since taking the tools to the pump did not work so well. On day 3 I could refit a ready assembled seawater pump.

Granted, a professional would have all the necessary tools at hand, but still the design is such that time is wasted servicing it. Volvo Pent spare parts are expensive enough, I dread to think what it would cost to have an authorized Volvo Penta serviceman do this job.